Feeding Trouble Caused by Characteristics of Material

In case material to be fed have kinds of special characteristics, some types of feeding trouble might be caused. We explain typical troubles as follows.

The following 3 types of trouble are caused mainly because of material characteristics.

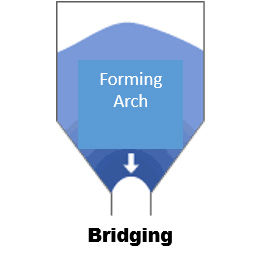

(1) Bridging

It is called “Bridging” that phenomenon which powder get stuck around outlet, blocking outlet part of hopper where powder particle is forming arch structure. As picture shows, only part of powder above outlet is fed, but it is limited amount only. In this situation, the material is not fed into feeding part like screw and belt etc, no matter how much feeder motor rotate.

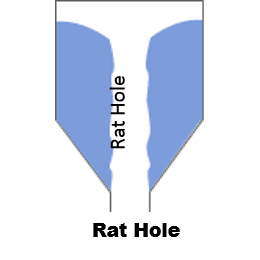

(2) Rat Hole

Because powder material near inner hopper wall is pressed against wall by powder pressure, friction between powder particle and wall become large and it is difficult to flow down. So as the picture shows, part of powder above outlet come down at first, and the material above is gradually follow. And in case the powder material around outlet part is stuck, the material feeding is stopped and forms a hole so called “Rat Hole”. Even feeding is not completely stopped and some material is fed, the material leftover stay cone part of hopper. Then, the material leftover makes fixed layer if it is not cleaned up, the characteristics may change as time proceeds.

Bridging and Rat Hole trouble are caused when power material have such tendency as strong adherability, large angle of repose, large difference of bulk density between soft and hard. Also, it is often seen such material as being easily intertwined like pulverized material. It is generally called “Bridging Tendency”, those material which easy to make Bridging and Rat Hole.

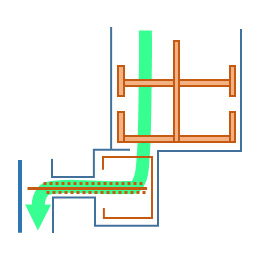

(3) Flushing

Flushing tendency is the characteristics that can cause jet flow of material. It means, air and material are mixed easily and the material including much air flow like liquid. It is measured that material is put into a 100cc container up to half level and shake it. When we see how material moves, if the surface of material waves like water, flushing tendency is high and it might cause the following troubles.

- When material is put into feeder from above, flushing flow of material never stops through screw and discharge tube. It is not limited to first input of material, in case of flushing tendency is extraordinary high, it may happen in refilling material.

- Due to flushing flow, the control may not come back stably after volumetric drive mode during refill. Also, it may feed more material.

- Feeding accuracy become worse due to low fill factor of material into screw.

- It take time for material to be deaerated when material is refilled.

- MV and flow capacity do not increase commensurately.

SUMMARY

Material characteristics may cause troublesome problem. However, if we can understand such information beforehand, it is possible to avoid such problem by selecting appropriate feeder model, screw and optional parts. Kubota have abundant performance of sales and manufacturing of Feeders over 35years history and test record in FTC. Kubota can feed those material that is said difficult to handle, using our technology, knowledge and know how built up in our past experience.