Screw Types and Characteristic for Gravimetric Feeder

In this issue, we explain feeder screw type and how it can be used. It is important issue to select appropriate feeder parts to get best performance of Gravimetric Feeder.

(1) Importance of Screw

Screw is the most important selected parts for screw feeder. Feeding rate and accuracy is influenced much by feeding status, because the material are fed by screw. The performance of Gravimetric Feeder changes according to the selection of appropriate parts, so the selection of screw parts is proprietary technology know how of feeder maker.

It is the mechanical structure that, by rotating screw, the blades of screw push material forward and convey it. In Gravimetric Screw Feeder, there are single screw type which conveys material by single screw and twin screw type which conveys material by twin screw. The following points are common for single and twin screw feeder.

- If the screw surface and material do not run smoothly, the material might adhere to the screw, also material and screw rotate together at the same time. It might end up to feeding trouble.

- In case the screw rotation speed is high and screw pitch is too large against its diameter, the fill factor of material to screw become lower, because screw blade flick the material outside.

- If the screw and material make friction all the time, it is not favorable for those material which changes property when it is sheared.(Ex. Glass Fiber, Low Melting Points Material etc)

- The clearance between screw and discharge tube need to keep appropriate balance. If the clearance is too small, the material bite between screw and discharge tube, it might cause allophone, crack, and break. If it is too large, the material forms lump and it will drop down, which deteriorates the feeding accuracy.

Feature Comparison Single Screw and Twin Screw

| Single Screw | Twin Screw | Remarks | |

|---|---|---|---|

| Cost | Low | High | Twin screw is more costly, because of design of gear box and the number of screw. |

| Flow Capacity | Large | Small | Comparison of the same size NX feeder case |

| Pulsation | Large | Small |

Pulsation of twin screw is small because ; 1. Phase difference of twin screw 2. High rotation |

| Material Coverage | Low | High | Twin screw can handle adhesive material |

(2) Single Screw

Very simple design to feed material by single screw. Some different types are available.

| Type | Design | Characteristics | Feeder Model | Adhesive Material | Flashing Material |

|---|---|---|---|---|---|

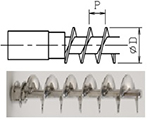

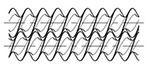

| BS Type BS:Blade Screw |

|

Blades in forms of plate is coiled in the peripheral of screw shaft. It can feed pellet, granule and GF, which has no adhesive tendency. 【Good Points】 Area of blade conveying material is large, so it is possible to feed large flow capacity. Also it can control flashing of material, but its effectiveness is limited. 【Weak Points】 It is not suitable to feed such material as high adhesive and clumping, because material adhesion rows on the surface of blade. In worst case, adhered material fulfill the gap of screw and stop feeding. |

NX-S CE-S BW-○○-2、4 CE-M |

Not Good | Good |

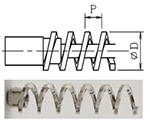

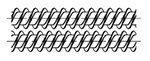

| OS Type OS:Open Spiral |

|

Spiral screw with hollow shape design. 【Good Points】 Open spiral type screw is low in stiffness, and a little more flexible like spring. It can feed high adhesive and clumping material, because open spiral configuration prevents material adhesion. 【Weak Points】 In case of having center shaft, material stick to the gap between shaft and screw, and it might cause problem to lower the flow rate. |

NX-S CE-S BW-○○-2、4 CE-M |

Best | Not Good |

| OS Type (Knife Edge ) |

|

OS screw with chamfered sharp edge (Upstream half side) 【Good Points】 Normal OS screw press material inside of discharge tube by scraping outer periphery of screw. When it reaches to limit, material lose to escape and motor torque increases, and finally the screw might break. Knife edge design can protect it. |

CE-M | Best | Not Good |

(3) Twin Screw

Design to feed material by twin screw. In case of concave type screw, the main feature is that each screw engage the other and drop adhered material compulsory from screw, which is so called “Self-Cleaning” function.

| Type | Design | Characteristics | Feeder Model | Adhesive Material | Flashing Material |

|---|---|---|---|---|---|

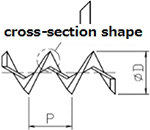

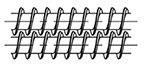

| MS Type ※Concave Type |

|

Arc shaped and concave design screw engages each other. 【Good Points】 Engaging each other with small clearance,it cleans up the other side of groove. Also, flash protection function is high, because of small clearance. 【Weak Points】 In case the size of pellet is large, concave type is not suitable, because the material bites in between of the screw. |

NX-T CE-W CE-T |

Best | Best |

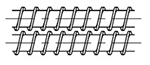

| PS Type ※For Pellet |

|

Screw with small blade in forms of plate is coiled 【Good Points】 Screw keep a certain clearance, so pellet material do not bite. PS type is suitable for smooth flow material. 【Weak Points】 Because the area to feed the material is small. the material need to have a certain size like pellet. Otherwise, flow capacity become low. |

NX-T CE-W CE-T(BSP type) BW-○○-3,5 |

Not Good | Not Good |

| FS Type ※For Fiber |

|

Screw with small width blade in forms of plate is coiled, and the screw clearance is smaller than PS type. 【Good Points】Suitable for fiber material. Larger blade area than PS push the material forward, giving less shear stress. 【Weak Points】In case pellet size is large, FS screw is not suitable because material bites. |

NX-T CE-W CE-T(BS type) BW-○○-3,5 |

Good | Not Good |

SUMMARY

We hope you would understand each characteristics of screw types and how it is used. Kubota have abundant technology know how to make the best choice of parts to meet customer’s technical needs based on feeder test experience over 10,000 cases.