What is Feeder?

Feeder is the equipment to feed the material like Pellet, Granule, Liquid etc. to the next process like twin screw extruder at preset constant flow rate. It is mainly used in plastic compounding, film, food and pharmaceutical industries.

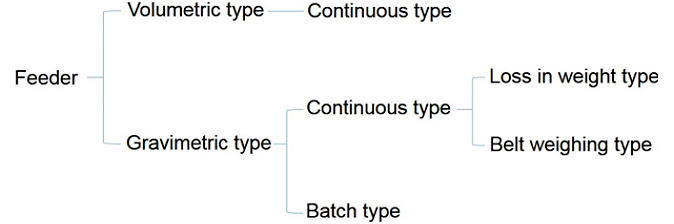

(1) Volumetric and Gravimetric Type

There are two types in Feeder, One is Volumetric Type and the other is Gravimetric one.

(a) Volumetric Type

Volumetric Feeder consist of hopper part keeping material inside and feeder part to feed the material. And mainly screw feeder is used to feed the material. Volumetric type of feeder feed continuously a certain volume of the material at fixed rate of rotation. But the actual flow rate by Volumetric Type of Feeder is unstable even at the fixed rotation, when it feed powder material because of the following 3 reasons.

1) Bulk density (weight per unit volume) and flow ability varies due to its air content.

2) Material pressure inside hopper changes due to material amount inside hopper

3) The screw conveying efficiency is not constant due to stickiness of the material to screw and other parts.

Gravimetric Type of Feeder solves that kinds of technical issues.

(b) Gravimetric Type

The Gravimetric Feeder realize continuous feeding with high accuracy, because it weighs the loss in weight value by weighing unit combined and controls its screw rotation speed etc. based on PI control. Also it can safely control the running status, since it has such functions as detection of the weight of hopper, lower and upper limits signal output, running history output and error detection.

(2) Continuous and Batch Type

There are two types in Gravimetric Feeders, Continuous Type and Batch Type.

(a) Continuous Type

Continuous Feeding is used to feed the material continuously to the downstream process. Flow rate is usually set by per hour, since its flow is continuous. P/I control is used to realize the stable and consistent feed, the details on this will be mentioned in (3)-(a), Loss in Weight Type.

(b) Batch Type

Batch Weight Feeding is used as another type of feeding. Batch Weight Feeding is used to feed the material to reach the pre-setting weight value within a certain minutes of time. In Batch Weight Feeding, two step of control is used. It starts to feed the material with large feed rate (=Large Flow) until it reaches to a little before setting value. And it switch over to small flow rare (=Small Flow) to achieve the setting value precisely.

(3) Loss in Weight and Belt Weighing Type

There are two types in Continuous Gravimetric Feeders, Loss-in-weight and Belt Weighing Types.

(a) Loss in Weight Type

The Loss In Weight Type consist of three parts, Hopper part to keep the material, Feeder part to feed the material to next process, and Weighing part to weigh the whole unit. Feeder part is selected from Screw Feeder (single or twin screw), Vibratory Feeder and Pump etc. based on the characteristics of the material to be fed. Based on the comparison of actual loss in weight value and target weight value which is calculated by the accumulation of setting value and running time, it continuously controls and makes the difference from target value to get close to Zero by PI control. That is, if the actual weight value exceeds the target, it increases the screw rotation. And if it falls below the target, it decreases the screw rotation. The Loss in Weight Type is suitable to feed main, sub, and additive material to cover the flow rate from small to middle range.

The Loss In Weight Type consist of three parts, Hopper part to keep the material, Feeder part to feed the material to next process, and Weighing part to weigh the whole unit. Feeder part is selected from Screw Feeder (single or twin screw), Vibratory Feeder and Pump etc. based on the characteristics of the material to be fed. Based on the comparison of actual loss in weight value and target weight value which is calculated by the accumulation of setting value and running time, it continuously controls and makes the difference from target value to get close to Zero by PI control. That is, if the actual weight value exceeds the target, it increases the screw rotation. And if it falls below the target, it decreases the screw rotation. The Loss in Weight Type is suitable to feed main, sub, and additive material to cover the flow rate from small to middle range.

(b) Belt Weighing Type

Belt Weighing Feeder Types feed the material on the belt by rotation of conveyor belt. The material is delivered to the belt from the above chute and/or screw feeder etc. Weighing unit is built under the belt to detect the weight within a certain length on the belt. By the multiplication of the weight and belt speed, the instantaneous feed rate is calculated. Also the feeding weight is found by the integration of instantaneous feed rate. Belt Weighing Feeder control the belt speed to achieve the setting value as same method as Loss in Weight Type as mentioned above. The Belt Weighing Feeder is suitable to cover large flow rate of main material.

Belt Weighing Feeder Types feed the material on the belt by rotation of conveyor belt. The material is delivered to the belt from the above chute and/or screw feeder etc. Weighing unit is built under the belt to detect the weight within a certain length on the belt. By the multiplication of the weight and belt speed, the instantaneous feed rate is calculated. Also the feeding weight is found by the integration of instantaneous feed rate. Belt Weighing Feeder control the belt speed to achieve the setting value as same method as Loss in Weight Type as mentioned above. The Belt Weighing Feeder is suitable to cover large flow rate of main material.

SUMMARY

As written above, the gravimetric feeders are used to feed the bulk material accurately by means of the most appropriate design depending on the type of material and application. And Kubota have advantage in the market of Gravimetric Feeder, because not only we have abundant know how on handling bulk material, but also we develop and manufacture weight sensor “Digital Load Cell” by ourselves, which is one of the key technology for Gravimetric Feeder.