What is Load Cell?

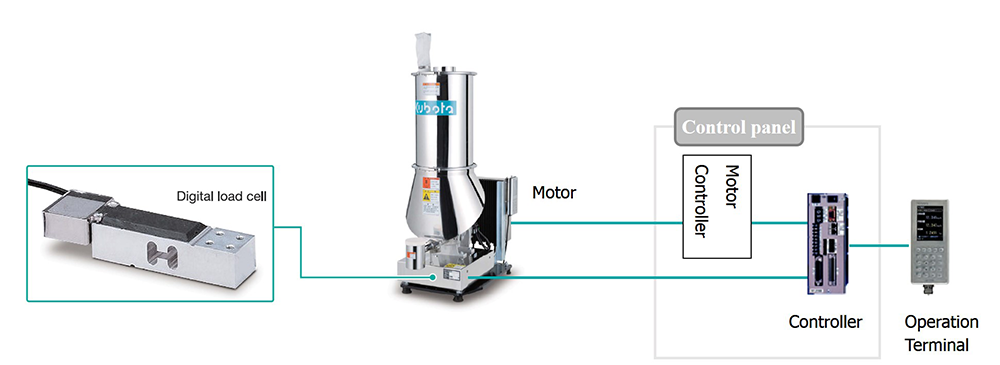

Load Cell is Weighing Sensor that output electronic signal which is transform by Load (N: Newton= Force). The Load Cell is built inside Gravimetric Feeder and Weighing Scales which are generally used to measure the weight. It is called Indicator or Controller which show the weight (Kg etc.) transformed from electronic signal.

In case of Gravimetric Feeder, in popular case, Load Cell is placed inside platform of Gravimetric Feeder, which is weighing the whole part of feeder including hopper, gear box, screw part etc. Load Cell detect the weight of material to be fed by loss in weight. As loss in weight feeder, Load Cell is indeed one of the most important key components for Gravimetric Feeder. In this article, we explain basic technology and type of Load Cell.

(1) Electronic Wiring Resistance Type Load Cell

Generally speaking, what is call Load Cell means Electronic Wiring Resistance Type Load Cell. Kubota Load Cell also adopt this Electronic Wiring Type. It is also called Strain Gauge Type.

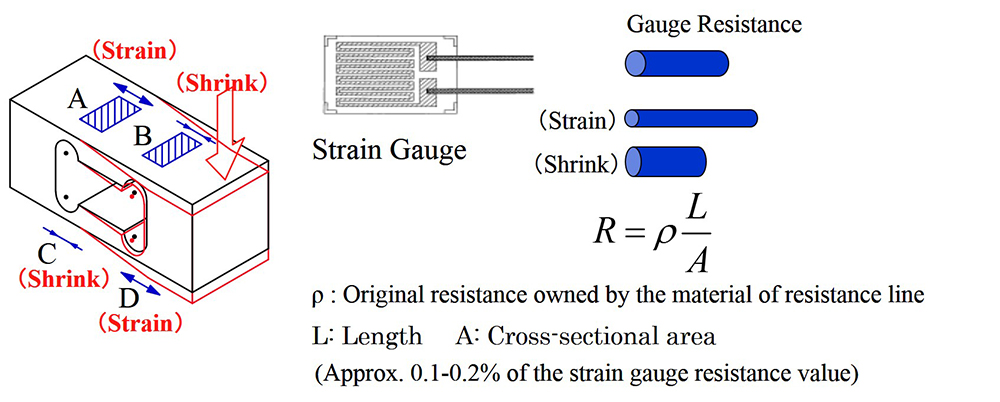

(a) Weight Detection Principle of Electronic Wiring Resistance Type Load Cell

Metal is transformed only a little when it is loaded. This transformation is converted into weight value. More specifically, a strain gauge is adhered to the metal that is called element (Please see the picture below). The strain gauge transforms in accordance with the overstress of the metal, electronic resistance value changes by the increase or decrease of electronic resistance. For example, when the resistance line is strained, the strain gauge is also strained, and the electronic resistance is increased by the decrease of cross-sectional area. The weight vale is calculated by detecting the change of electronic resistance through electronic circuit.

(b) Characteristic of Electronic Resistance Type of Load Cell

The electronic resistance type of load cell has the following characteristics.

- Simple structure, possible to measure with relatively high resolution

- Cover wide range of weight value from hundred gram to thousand Kilogram, which depends on the shape and size of the element

- Small and light weight, compared with other types of weight detection method

- Tough and easy to handle

(2) Analogue Load Cell and Digital Load Cell

There are two types in Electronic Wiring Type Load Cell, Analogue Type and Digital Type.

(a) What is Analogue Load Cell?

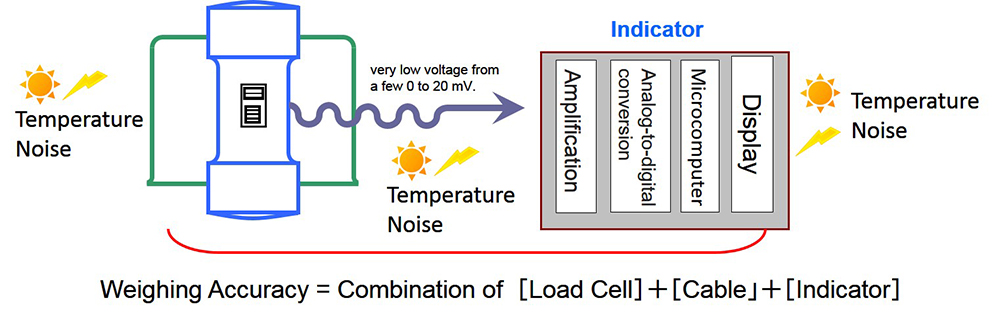

Analogue Load Cell output analogue signal (very small electronic voltage) through cable and it is changed into digital by indicator. There are following three factors which analogue type load cell might cause error.

- Indicator and Cable may become the cause of error in addition to that of load cell. (When the cable and/or indicator is replaced by maintenance work or repair, the adjustment by test weight is necessary.)

- Each item of Load Cell, cable and indicator are affected by ambient temperature.

- Analogue signal is affected by noise when it is transmitted from Load Cell to indicator, because the signal is very low voltage from a few μV to mV.

These problems are solved by Digital Load Cell mentioned below.

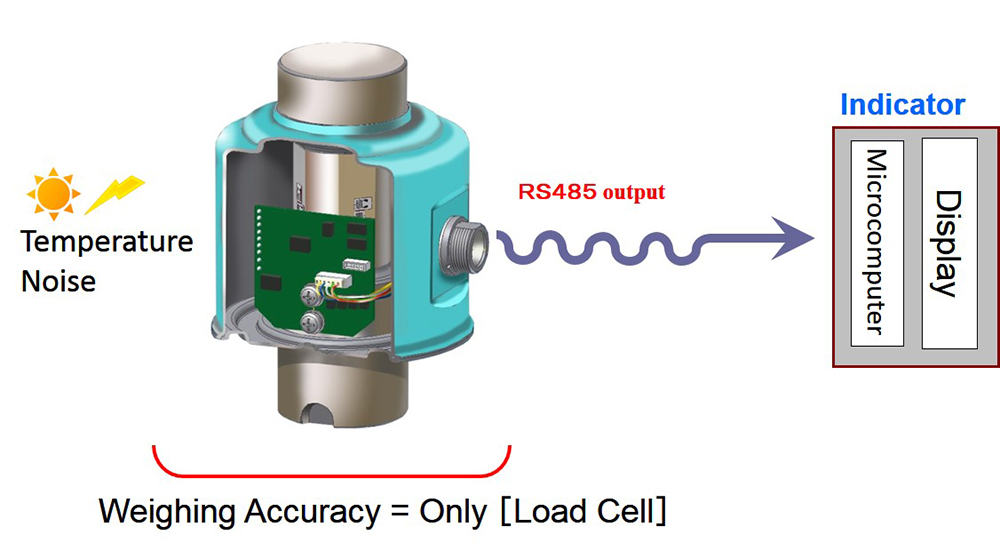

(b) What is Digital Load Cell?

Digital Load Cell converts analogue signal into digital one by load cell side. And it automatically adjusts output error caused by change of temperature, because temperature sensor is built inside. That is, Digital Load Cell have the following benefits

- Weight value is not affected by replacement of indicator, cable in case of repair and maintenance work. And adjustment by test weight is not necessary. It saves time and cost for repair.

- Stable weighing is possible, because Digital Load Cell is not affected by temperature change. Digital Load Cell output digital signal of weight data which is internally adjusted to correspond with temperature change.

- Very little affection against noise as Digital Load Cell is using digital signal with several V.

- Furthermore, because Digital Load Cell have achieved Max. 419 million internal resolution, it is possible to control weight value with higher resolution compared with our conventional type of Analogue Load Cell.

SUMMARY

Load Cell is the most important component to measure the weight. It is not too much to say that quality of load cell directly affect that of Gravimetric Feeder. Kubota is the leading company that developed Digital Load Cell the fist in Japan. Kubota have the strength that develop and manufacture not only Gravimetric Feeder but also Digital Load Cell that the key technology for Gravimetric Feeder. As the pioneer of Weighing Equipment market, we have abundant experience and confidence on the quality of measurement of the weight, which is supported by the history over 90 years old.