What is Accuracy of Feeder?

Because gravimetric feeder is an equipment to feed material with constant feed rate, it is necessary to quantitatively indicate accuracy concerning constant feeding capability as one of performance indicator of gravimetric feeder.

Kubota use following 2 types of accuracy.

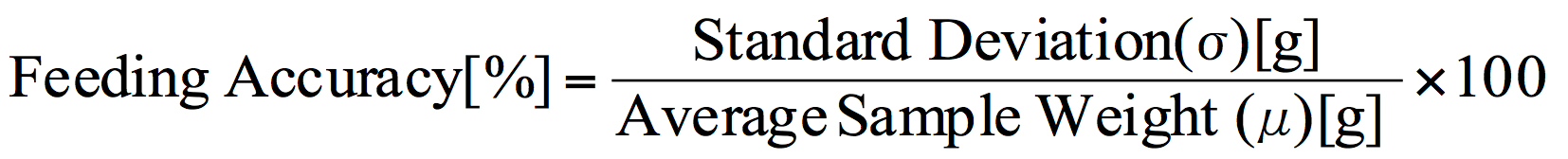

- Feeding Accuracy; measures the expected variability of discharge stream

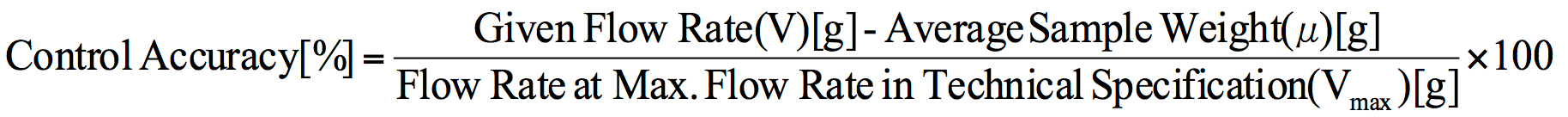

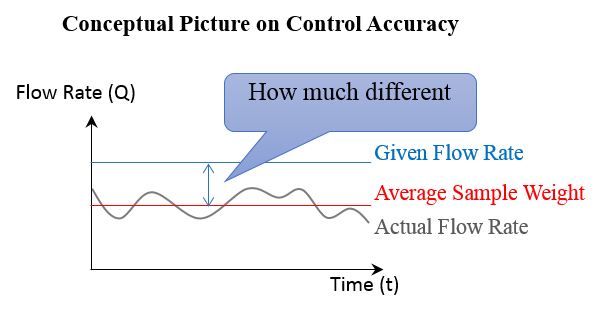

- Control Accuracy; shows gap between actual output and given flow rate

Feeding Accuracy and Control Accuracy are measured based on the same interval and consecutive samples of output.

(1) Feeding Accuracy

Feeding Accuracy measures the extent of discharge variability at a given flow rate. The definition of the period of time changes depends on feeder model, the output of 10 consecutive times of samples is used as sampling data.

Unit time of Loss in Weight Type Feeder

- 1 minute

- Time taken for 60 times of screw rotation

- Feeding time of 1% of capacity,whichever takes longer.

Unit time of Belt Weighing Feeder

- 1 minute

- Time taken for 1 time of belt rotation whichever takes longer.

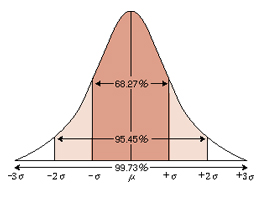

The variation of feeding output can be quantified by average sample weight (μ) and standard deviation (sigma,σ). Normally, the output measured in every unit time is normally distributed symmetrically centering average sample weight (μ). In normal distribution, 68.3% among all data is distributed within a range of average sample weight (μ) and standard deviation(σ).It is defined as Feeding Accuracy that the standard deviation(σ) is divided by average sample weight (μ). Feeding Accuracy is better number when it closes to zero.

*Assuming that material fill factor into screw is constant in manual operation, the fluctuation of screw is an only factor of variation of sampling data. Thus, the standard sigma become same value, even if the number of screw rotation is 100+α or 10+α. As understood from this, when the average sample weight value is large, Feeding Accuracy become well, and when it is small, Feeding Accuracy become worse.

*The definition of sample unit time is mentioned above, in most of the cases it is measured by taking a series of 1 minute consecutive catch samples from discharge stream. (In case of feeding test at FTC and in-house test before shipment) To measure accuracy in large flow rate, it is possible to take less than 1 minute consecutive sample. In that case, Feeding Accuracy look worse for the above mentioned reason, it is calculated based on 1 minute sample.

(2) Control Accuracy

Because Feeding Accuracy is to measure the expected variability, if there is no variability on data, its number become good even discharged amount is largely different from target flow rate. (Ex. Feeding Accuracy is good, if the given flow rate is 100kg and even the actual feeding rate is 50kg/h without variability)

On the other hand, Control Accuracy is to measure how much average sample weight (μ) is different compared with given flow rate (V). Control Accuracy shows how much different between given flow rate and average sample weight at unit time compared with given flow rate at Max. Flow Rate. Please note that definition of sampling data is as same as Feeding Accuracy, Control Accuracy can be calculated by the same data.

Because Loss in Weight Feeder is measuring loss in weight value as discharged weigh, there would be not so much variability in Control Accuracy. On the other hand, because Belt Weighing Feeder is measuring discharged weight based on the weight on the belt passing through, Control Accuracy deteriorates, if there are shaves of belt and adherence of material to the belt. For this reason, Control Accuracy is important factor as well as Feeding Accuracy. (Unevenness of belt weight affect Feeding Accuracy)

SUMMARY

To understand the difference between “Control Accuracy” and “Feeding Accuracy” is important because it’s totally different.If you need, please ask to your sales person in charge to explain the difference of these accuracy. We always welcome your questions.