To Resolve Material Flushing

We explain about 4 types of technical counter measure for material flushing, which occur frequently.

- Discharge Tube with Front Valve

- Choice of Screw Design

- Inner Parts Selection, Buffer Plate and Horizontal Rotor

- Material Refilling Level Adjustment

(1) Discharge tube with front valve (Effective for first input of material)

By fixing valve at the front edge of discharge tube (vertical or horizontal), it is possible to stop flushing of material for the first input of material into hopper. After input of material for the first time and a few minutes passed, flow ability become lower due to air escape from material. Then material flushing are not seen much in opening the valve.

*However, in case of strong flushing material, flushing occurs in refilling of the material. Since valve cannot close in running of feeder, the valve is not effective measure.

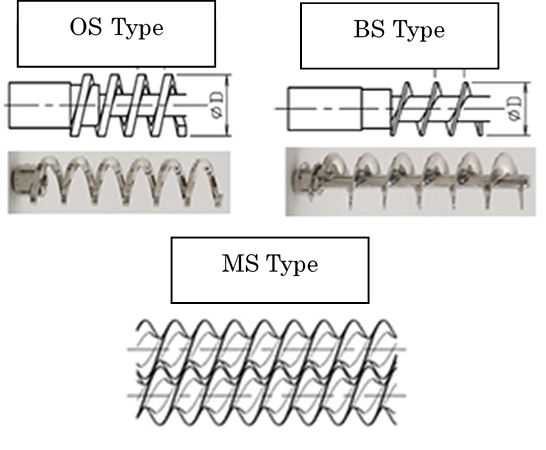

(2) Choice of Screw Design

In case of single screw feeder, material flushing can be prevented more or less by using BS type screw (Blade design) rather than OS type (Open Coil). In case of twin screw feeder, MS type (Concave design) is effective. Clearance between screw and discharge tube need to be minimized within allowable limit.

*However, strong flushing powder still flush through the narrowest gap.

(3) Inner Parts Selection, Buffer Plate and Horizontal

Special optional parts for Kubota feeder, model CE-S and CE-E. Those parts makes roundabout trip of material and reduce the gap between parts. So it is effective to make rough flow of the material from hopper inlet to discharge tube.

*However, even using these parts, very strong flushing powder still flush through the narrowest gap and feeding rate exceeds over the setting value.

(4) Material Refilling Level Adjustment

Flushing of material can be decreased by increasing refilling level of material which cause cushion layer of material thicken against flowing material from the above in refilling. It is easy to try since it can be done by setting change.

But it should be remembered that increase refilling level increase the number of material refilling which shorten the time of gravimetric control mode as a result.

SUMMARY

We have focused material flushing which is always troublesome area for bulk material handling process. It is often seen that flushing material also cause bridging trouble once air in material come out. In our recent experience, those type of difficult to handle material is increasing in cutting edge technology area like lithium ion battery manufacturing process. Kubota can support customer by providing the best solution to fix your powder handling issue.