How to handle Refilling of Material in Gravimetric Feeder

Once gravimetric feeder starts to feed the material, obviously the material in the hopper becomes less. When the material reached to low level, it is necessary to be refilled. So in this issue, we explain the following two points.

- How gravimetric feeder is working during the material is refilled

- Selection of refilling device depends on material characteristics

(1) How gravimetric feeder is working during the material is refilled

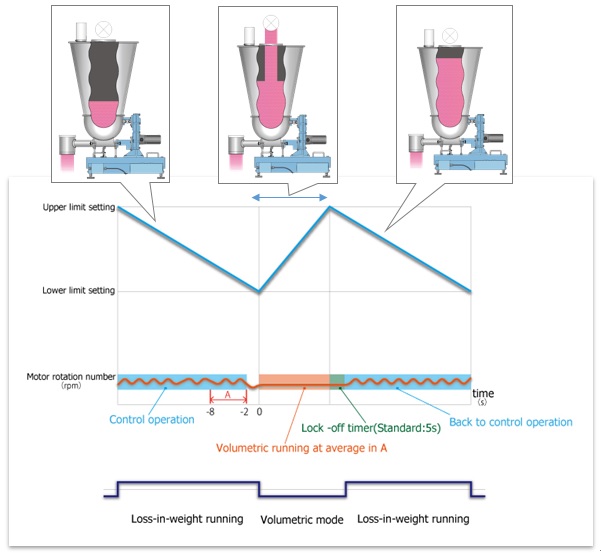

During the refill of material, gravimetric feeder runs in a different way compared with normal running status.

When gravimetric feeder is running normally, it measures the loss in weight in hopper and controls the feeding material amount by controlling screw motor rotation speed.

However, during material refilling time, because the weight in hopper is increasing, it cannot measure and control the feeding material. Therefore, it keeps running under “Rock Drive Mode”, which fixes the feeding screw rotation speed. During this operation, it is assumed that “PV(Present Value)=SV(Set Value)”, the screw rotation speed is fixed to the number just before 8 to 2 seconds of staring “Rock Drive Mode”. So during the refill, gravimetric is actually running under volumetric feeding mode.

Normally, the number of material refilling should be less than 10 times per hour. Also, it is recommended to design feeding capacity as 10 times large as that of gravimetric feeder. For example, if the feed rate of gravimetric feeder is 100kg/h, refilling capacity need to be 1000kg/h.

Selection of refilling device depends on material characteristics

The refilling device need to be selected among many different types depending on characteristics of material. We show a matrix to select refilling devices based on material characteristics.

| Pellet(*1) | Granule | Powder(*4) | |||

|---|---|---|---|---|---|

| No Flush No Bridge |

Flush | Bridge | |||

| Cut Gate | ○ (*2) |

○ | × Leaking of material(*3) |

× Leaking of material |

× Bridge in Chute |

| Slide Gate | ○ | × Biting |

× Leaking of material |

× Leaking of material |

× Bridge in Chute |

| Knife Gate | △ Biting |

○ | ○ | × Leaking of material |

× Bridge in Chute |

| Screw Feeder(*5) | △ Biting |

○ | ○ | △ Leaking of material |

△ Bridge in Chute |

| Rotary Feeder | × Biting |

△ Biting |

○ | ○ | △ Bridge in Chute |

| Circle Feeder | × Biting |

○ | ○ | △ Leaking of material |

○ |

*1 Material characteristics are supposed to be commonly used one.

*2 The mark used in the tables means as follows.

○:Good、△:Not So Good、×:Not suitable

*3 The remarks explains the reason why it is not suitable.

*4 It is recommended to consult with Technical Dept. and/or to do powder test, when mixed powder is handled.

*5 Feeder part is used for refilling device with volumetric mode.

SUMMARY

Because the basic technology of gravimetric feeder is Weighing and Feeding, it cannot measure the weight when the material is being refilled. It is useful to know the fundamentals how it works. Regarding refilling devices, it also have technical know-how, and if the refilling device that does not fit into the characteristics of material is selected, it would cause trouble like powder leakage.Kubota can support customer not only to select appropriate type of refilling device, but also supply them based on abundant experience.