Liquid Feeders

Liquid Loss-in-Weight Feeder is to handle liquid material. Liquid Feeder is popular to feed additives like flame retardant, plasticizer, lubricant, oxidation inhibitor and foaming agent. Or, some solid material that is difficult to handle by screw feeder can be fed easily in liquid form.

In this basics, we explain about liquid material related to Gravimetric Feeder, because liquid material have different characteristic from powder and pellet.

(1) Viscosity

In fluid material, there are a lot of kind like air, water, oil, paint etc., the stickiness is expressed by the

like “Smooth” or “Thick”. “Viscosity” is used to express it in a quantitative way. For instance, more power is required to stir sticky material like thick malt syrup compared with stirring water. Unit of viscosity is cP. 1. cP is equal to 1mPa.

In most of the cases, Viscosity of material become lower, when the material temperature become high. Water is also the same, 1.8cP at 0°C, 0.282cP at 100°C. Therefore, it is impossible to design Liquid Weighing Feeder, if the viscosity of the material is unknown when it is fed. The table 1. shows the familiar material viscosity at 20~25°C. The viscosity is subject to change because of its state and brand, please note that it is guideline purpose only.

Table.1 Guideline of Material Viscosity

| m Pa・s | |

| Water | 1 |

| Worcester sauce | 5~10 |

| Vegetable oil | 60~80 |

| Shampoo | 2000~3000 |

| Dressing | 5000~10000 |

| Syrup | 10000 |

| Mayonnaise | 15000~20000 |

| Thick malt syrup | 20000~25000 |

| Tomato ketchup | 30000 |

| Strawberry jam | 55000 |

| Hand cream | 100000 |

| Mustard | 150000 |

(2) Congeal point and Melting point

It is called Congeal point that the temperature of liquid material to get solidified. Melting point is the temperature of solid material to start melting. Please note that Congeal point and Melting point may be different in some material. Liquid Feeder is the machine to feed liquid through pipe, it is premised that the temperature of liquid material should be more than Congeal point. Also, if the material is solid state at ambient temperature and its Congeal point is more than Zero, it is desirable to keep the temperature more than 20°C of congeal point while it is running. Because the temperature might be varied against setting value in heated part like pipe, hopper and pump part and non-heated part of the Liquid Feeder. So, high temperature need to be set not to exceed below the congeal point even if the temperature is not uniform in all part.

Also, if the material is solid at ambient temperature, all of material inside must be fed completely, when heater power is turn down. In case the material is left inside the pump, it might cause trouble for solidified material to bite into driving part of pump, if the worse comes to worst.

(3) Pumping Pressure of Liquid Weighing Feeder

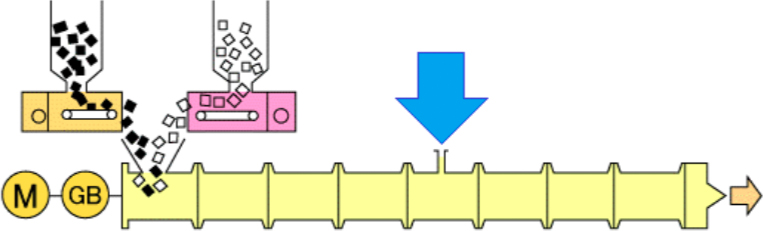

When liquid material like additives (flame retardant, plasticizer and foaming agent etc.) is fed into extruder, it is often seen for the material to be pumped into the middle of extruder as indicated arrows in the illustration as below.

Because the extruder is the equipment that mix and extrude melted resin material with twin screws, internal pressure becomes higher at the closer end of equipment. Therefore, Liquid Loss-in-Weight Feeder might be requested to feed the material with high pressure. If the pumping pressure is lower than that of inside the extruder, not only Liquid Gravimetric Feeder cannot feed liquid material into extruder, but also melted resin inside nozzle might get back pressure. It might cause malfunction of Liquid Feeder. (But nozzle from of Kubota Liquid weighing feeder is small, so the possibility is very low.)

SUMMARY

As explained above, the unique technology is necessary to handle liquid material. Kubota have abundant know how of Liquid Weighing Feeder based on wide experience and reference in the past.