To Resolve Bridging

In feeding powder material, some trouble could happen as we featured “Feeding Trouble Caused by Characteristics of Material” before. In this issue, we would like to explain some counter measures to resolve material bridging trouble, which is most likely to occur and troublesome area for bulk material handling process.

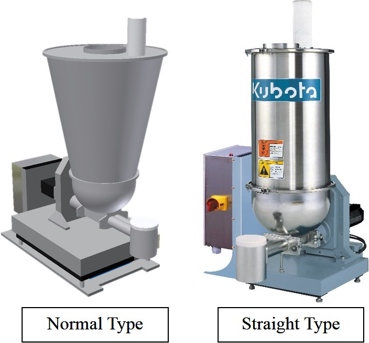

(1) Straight Hopper

By designing straight hopper from up to downward without corn, it prevents or decrease occurrence of material bridging caused by escaping of air. It is the most economical way, but it might not be so effective in case the powder is very sticky.

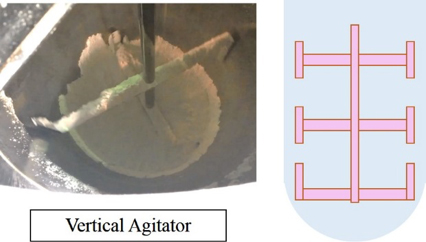

(2) Vertical Agitator

Vertical axis rotates from top of hopper to downward, some wings agitates overall material inside hopper. It can resolve material bridging almost completely, but it takes extra labor to disassemble and cleanup of the feeder, because it is difficult to remove long vertical agitator. Also it is costly, because it needs another motor and reducer on the cover of hopper to drive the agitator. Also, there is a weak point that material is left on the side wall of hopper and agitator wings which is pushed forward after all material feeding.

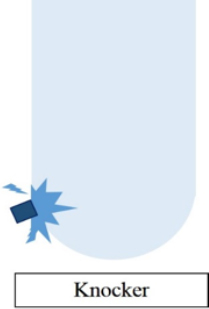

(3) Knocker

Knocker breaks material bridging by giving impact from outside. However, the impact give influence to weight change, it need to work when the loss in weight feeder is in volumetric mode. Also, knocker is attached in case the feeder hopper has more than 500L capacity, because the mount attaching knocker need to be welded and hopper strength against impact is required.

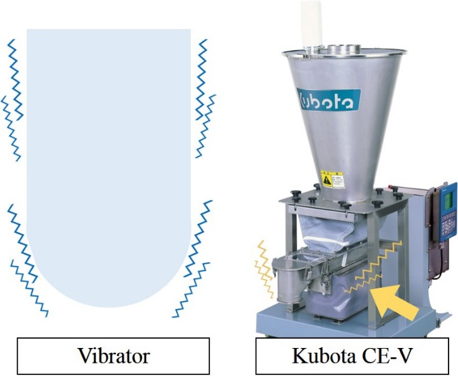

(4) Vibrator

Vibrator breaks material bridging by vibrating hopper from outside. However, vibrating hopper in normal state of material without material bridging, it may form material bridging as an adverse effect of vibrating by escaping air in material. So we usually do not use vibrator except chute part of CE-V feeder.

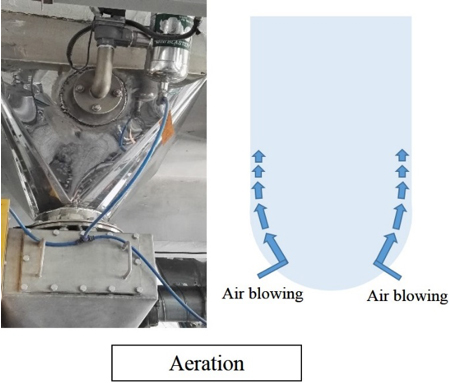

(5) Aeration

Aeration breaks material bridging by air blow in multiple part of hopper, which increase the flow ability of material. Because the variation of air pressure affects weight value, normally it is not used. It could be used in a hopper of refilling device. However, by refilling air rich powder because of aeration, it may cause another type of feeding trouble called “Flushing”.

SUMMARY

Kubota have been accumulating know how and do how on powder handling since we have developed gravimetric feeders.We have Feeder Technical Center in Japan, Korea, and China, where we are ready to serve our customer to resolve various kind of issue of powder handling. Also, we own feeders for demo and test use at customer site.